How Ozone Generators Work

You may have heard of an ozone generator, but you may not know how an ozone generator works. An ozone generator, or ozone machine, is a device that converts oxygen from various sources such as ambient air, dry air, or concentrated oxygen into ozone. Ozone generators produce ozone (O3) by adding energy to oxygen molecules (O2), which causes the oxygen atoms to part ways and temporarily recombine with other oxygen molecules. The ozone is then used for water disinfection and air purification. Ozone generators can come in small hand-held sizes, all the way up to large-scale industrial models that can produce several hundred grams of ozone each hour. Industrial ozone generators work very similar to ambient air units except they require very clean and very dry air or oxygen and have a corona cell specially designed to generate very high ozone concentrations.

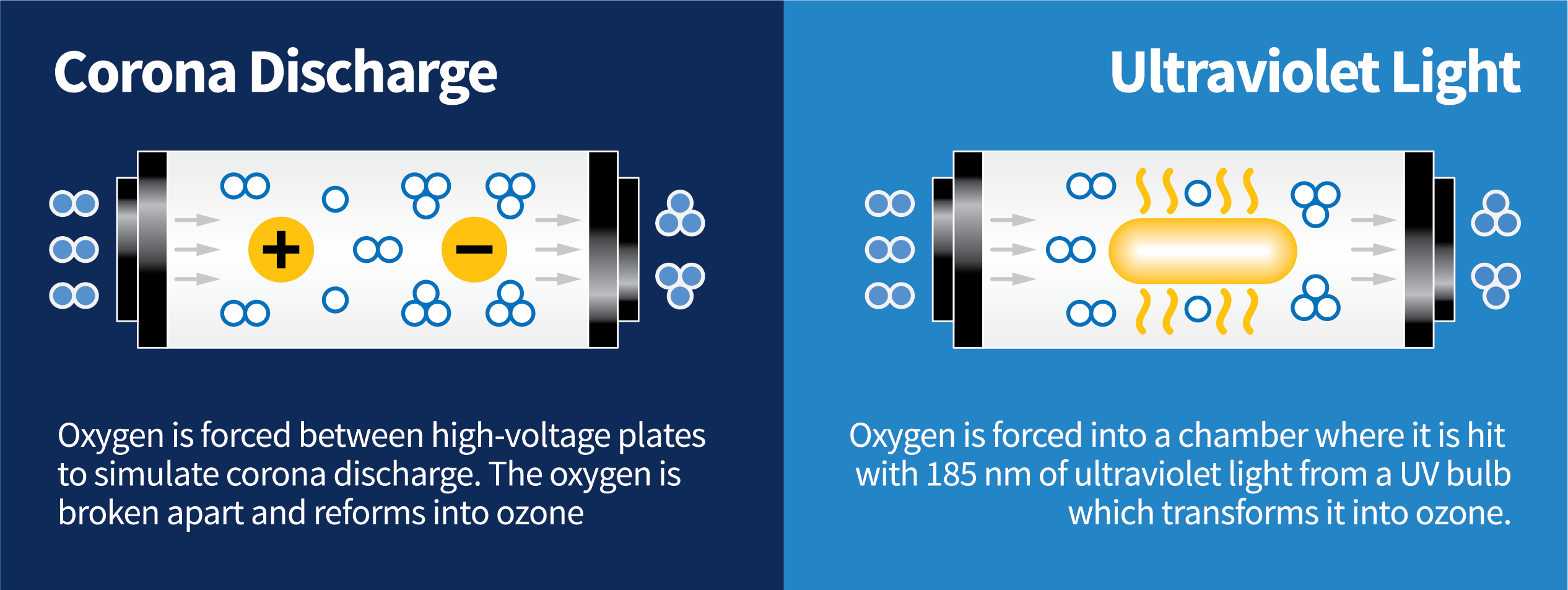

Ozone generators apply an electrical charge to the air that passes through. This splits apart some normal oxygen atoms into unstable single atoms, which bond with other oxygen molecules to form ozone. (Image not to scale.)

Once the ozone is produced it reacts with a pollutant, bacteria, virus, or mold, and breaks it down into less complex (and typically less harmful) molecules through a process called oxidation. Ozone that has not reacted with other molecules will decompose into oxygen over time. Ozonation destroys odors, and disinfects air, water, and other materials. It has even been approved by the USDA and FDA for use on food.

Although many manufacturers claim that ozone will render almost every contaminant harmless, it is important to follow safety guidelines, understand the structure of the contaminants, and have an ozone expert properly size the ozone generation unit.

Ozone Generation

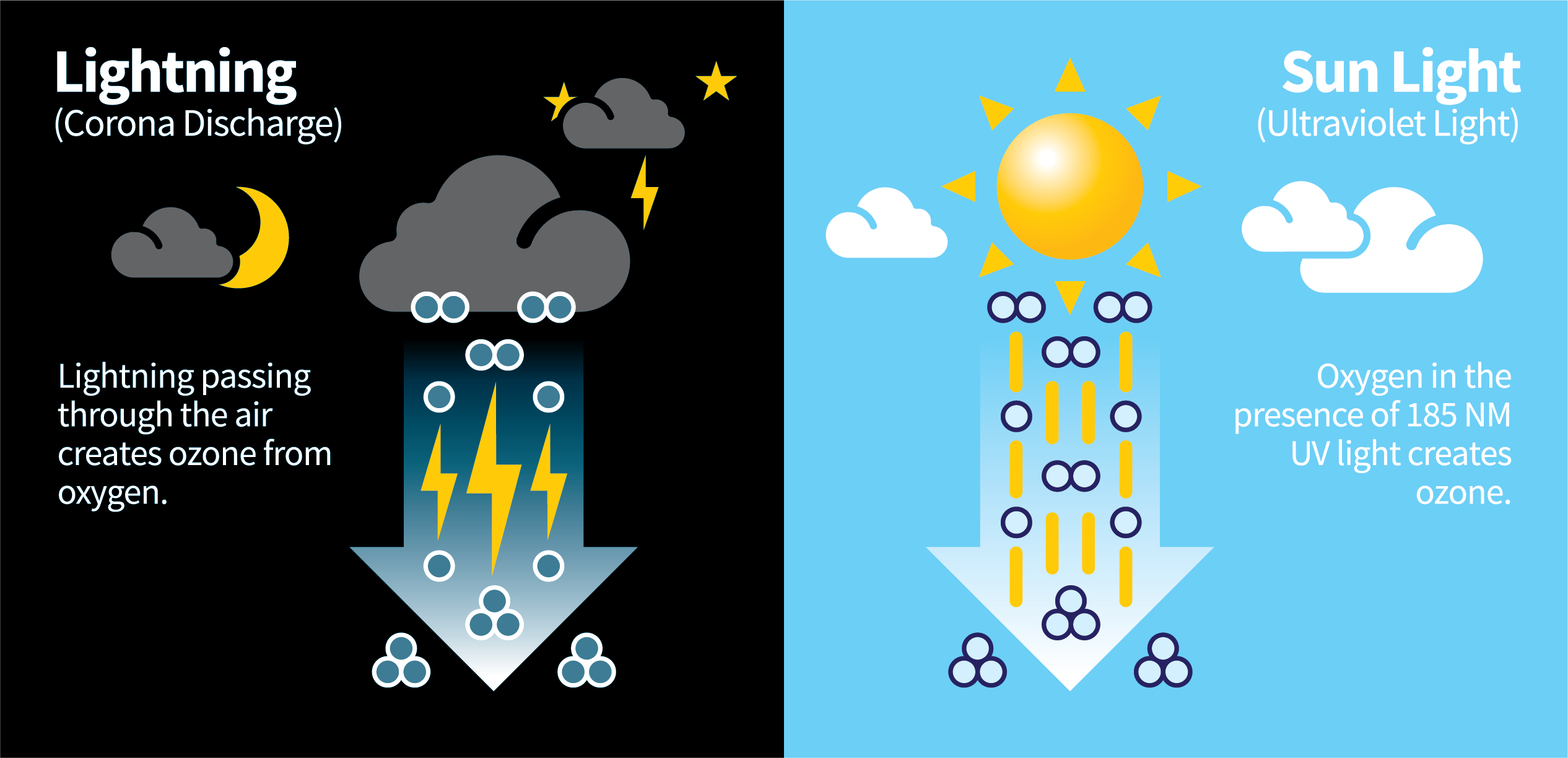

The ozone generation process occurs naturally in the environment in one of two ways: Lightning strikes or Sunlight. After a thunderstorm, we probably all recognize the smell of ozone. The fresh, clean, spring rain aroma that we notice after a storm is most often a result from nature's creation of ozone. The second method is ultraviolet light from the sun. Through this method, oxygen in the presence of the sun’s UV light can be broken down and form into ozone.

Ozone generators recreate these processes in a controlled setting. This leads into two types of ozone generators: Corona discharge generators and UV light generators.

Corona Discharge

These machines create ozone by taking oxygen and forcing it forcing it through a high voltage metallic grid. The high voltage splits apart the oxygen molecules into single atoms. These atoms then attach to other O2 molecules in the air to form ozone (O3.)

A few advantages of using corona discharge are that it creates a consistent ozone output, it generates high ozone concentrations, it provides fast organic (odor) removal, and it is ideal for water applications.

Ultraviolet (UV) Light

This process of ozone generation is similar to how the sun’s ultraviolet radiation splits O2 to form individual oxygen atoms. UV light changes oxygen into ozone when a wavelength at 254 nm (nanometers) hits an oxygen atom. The molecule (O2) splits into two atoms (O) which combine with another oxygen molecule (O2) to form ozone (O3). UV Light occurs naturally through the sun rays, but this process is considered to be less efficient than corona discharge, according to InterNACHI.

The advantages of using UV Light include a lower cost than corona discharge, it is simpler to assemble and use, and the ozone output using UV Light is less affected by humidity.

Types of Ozone Generation Feed Gas

Due to the instability of the ozone molecule, it has a short life. Therefore, it cannot be stored or transported. Ozone must be generated on-site. Depending on your specific application and/or limitations, ozone can be created from one of three sources: Ambient Air, Dry Air, or Concentrated Oxygen. Here is a breakdown of each option.

Ambient Air

Ambient Air refers to air that is available in the environment, whether it is indoors or outdoors. This source does not have a high concentration of oxygen, so it is used in machines that produce low levels of ozone.

Advantages:

- Free to use

- Readily available

Disadvantages:

- Requires regular corona cell maintenance

- Can cause electrical component failure due to dirt or insects that can get lodged in the corona cell or corona plate

Dry Air

Dry Air refers to air that has moisture removed so the dew point is -70° F or lower. This source will also produce low levels of ozone.

Advantages:

- Allows a consistent ozone output over time

- Reduces corona cell maintenance (very important)

- All dust and insects are removed

- Equipment is less expensive than concentrated oxygen

Disadvantages:

- Low concentrations result in low solubility in water

- Still results in some nitric acid production

- Systems are more complex than using ambient air

Concentrated Oxygen

Concentrated Oxygen refers to an oxygen supply, which is at least 90% pure, with moisture removed to a dew point of -100° F.

Advantages:

- Allows a consistent ozone output over time

- Eliminates corona cell maintenance (very important)

- Virtually all moisture is removed

- Ozone output is typically doubled (2x) vs. using dry air

- Higher concentrations means very soluble in water

Disadvantages:

- More expensive than dry air systems since more equipment is required

- Systems are more complex than using dry air (need compressor and oxygen concentrator)

Using concentrated oxygen typically provides 2x-3x the output of dry air, and 4x-6x the output of ambient air. It is important to remember that ozone generator output decreases as dewpoint (moisture content) increases. Click here for more information.

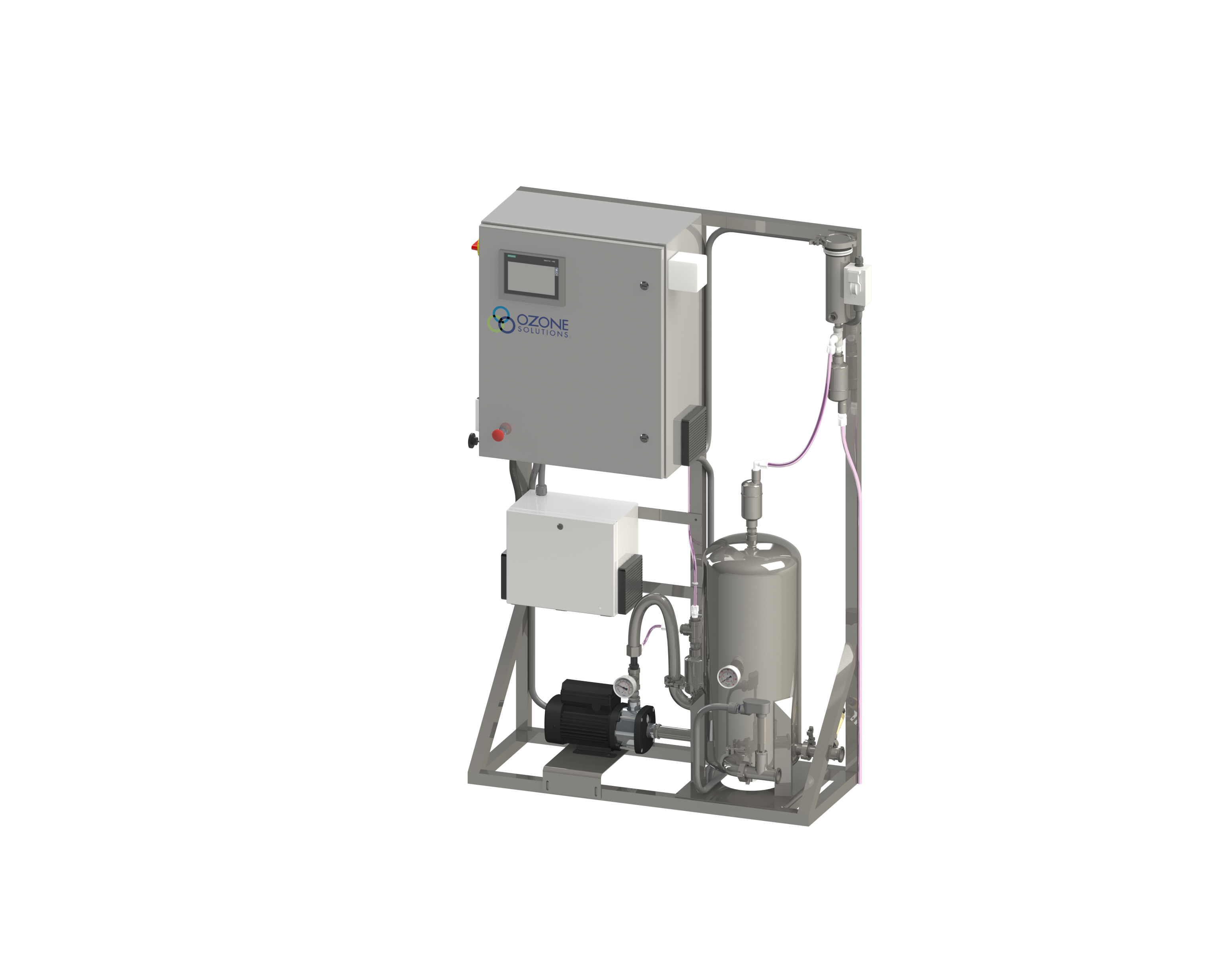

Types of Ozone Generation Systems

As discussed earlier, there are two methods of ozone generation, UV light and corona discharge. However, ozone generators can also be separated by another characteristic, aqueous versus gaseous ozone.

Aqueous Ozone Systems

Aqueous ozone generators are systems that inject gaseous ozone into water. The ozonated water

can then be applied to surfaces for disinfection or circulated in water systems. The applications are almost endless from food disinfection to clean-in-place (CIP) processes to wastewater treatment.

can then be applied to surfaces for disinfection or circulated in water systems. The applications are almost endless from food disinfection to clean-in-place (CIP) processes to wastewater treatment.

Compared with methods such as chlorine or UV disinfection, ozone is more effective at eliminating viruses and bacteria, while requiring very little contact time, thus reducing the overall treatment time while simultaneously leaving no chemical residues. Due to the high oxidation potential, ozone effectively degrades microbes and viruses, causing cell membrane rupture and decomposition of essential biomolecular components. This leaves the water clean and free of microbes and viruses.

An important criterion for many water treatment applications is there are no harmful by-products from ozone use. As ozone decomposes, it reverts to oxygen. Ozone treatment also inhibits regrowth of micro-organisms, provided that other processes have reduced particulates in the wastewater.

Gaseous Ozone Systems

Gaseous ozone generators can be used in a wide range of air treatment and odor mitigation applications. Ozone is circulated through the air to treat airborne contaminants, as well as contaminants that may be resting on exposed surfaces. By using ozone and its oxidation process, you can efficiently reduce or completely remove airborne odors and contaminants.

It is important to follow safety guidelines and regulations of ozone systems. Ozone shock treatments should be conducted in unoccupied spaces or by a professional ozone service partner like Ozone Solutions. Continuous ozone circulation at low treatment levels should only be conducted after consulting with an ozone professional, such as Ozone Solutions. This is to ensure that equipment is rated for continuous use, and that the proper safety mechanisms are in place to keep ozone levels within the acceptable threshold.

For more information on the right ozone generator for your needs, contact us today.